STEMAR L-ES AIR HUMIDIFIERS / AIR SCRUBBERS

STEMAR L-ES AIR HUMIDIFIERS / AIR SCRUBBERS

PERFECT SOLUTIONS FOR INDIVIDUAL REQUIREMENTS

Stemar L-ES is one of the leading manufacturers of humidification systems. Our product portfolio includes air scrubbers and circulating water spray humidifiers, bioscrubbers, fume scrubbers, low, medium and high-pressure humidifiers. Special designs and modifications to the dimensions of your unit are available upon request.

STEMAR L-ES AIR HUMIDIFIERS / AIR SCRUBBERS ARE CURRENTLY USED FOR THE FOLLOWING APPLICATIONS:

• Painting facilities in the automotive industry

• Textile industry

• Print shops

• Wood industry

• Chemicals industry

• Biofilters

• Environmental technology

• Recycling technology

• Clean technology

• Dust-free rooms

• Paper industry

• Tobacco industry

• Comfort air-conditioners in office buildings, banks, airports, etc.

THE ONLY HUMIDIFIER CAPABLE OF CLEANING PROCESS AIR

Fresh, clean air guarantees a healthy and pleasant atmosphere for well-being and productivity. However, working, living and communicating in closed rooms often leads to a decrease in air quality. Benefit from a healthy work atmosphere and let your employees breathe a sigh of relief – with an air scrubber from Stemar L-ES.

Stemar L-ES air scrubbers do more than just humidify the air: they are also the only humidifiers capable of removing harmful substances produced by process air technology found in the automotive industry, painting facilities and biogas plants, etc. from the air.

Stemar L-ES offers units with an air volume flow ranging from 200 m³/h to 1,000,000 m³/h.

Thanks to our in-house stainless steel production, we are one of the few manufacturers that produce units completely in-house. This guarantees particularly quick and flexible realisation of each project.

Needless to say, all of our humidifiers are designed according to the requirements of VDI 6022.

MADE IN GERMANY. EVERYTHING FROM ONE SUPPLIER.

• Consultation, planning, design and delivery of complete humidifiers/air scrubbers tailored to suit your needs made from stainless steel and fibreglass according to Stemar L-ES standards.

• Replacement parts for all air scrubbers available for quick delivery

• Repairs for fibreglass and stainless steel air scrubbers

• Demisters and demister cartridges for every application

• On-site installation worldwide by our service technicians

• UV disinfection of air-conditioning systems with state-of-the-art technology

• Analysis and consultation according to VDI 6022 guidelines

DEMISTERS

OPTIMAL RESULTS THANKS TO INERTIAL SEPARATION

Demisters are used in air-conditioning, ventilation and exhaust air systems to reliably separate droplets where required. As each of these applications has its own set of unique requirements, our staff are on hand to provide detailed advice for the design, planning, and implementation of your project.

All of the demisters used by Stemar work according to the principle of inertial separation widely used today. Inertial separation demisters consist of individual long profiles shaped for the relevant application placed next to each other at set distances depending on the application. When air laden with droplets flows through the demister, the drops collect in the demister pad – following the inertia effect – and are discharged through the guide ribs. Demisters vary in size, material and profile placement depending on the application criteria.

STEMAR L-ES DEMISTERS OFFER A WIDE VARIETY OF SIGNIFICANT ADVANTAGES:

• Optimal efficiency for the entire system due to high degree of separation

• Maximum droplet diameter up to 10 micron

• Available as ready-to-install units or as a complete kit including all mounting parts

• Select between either PPTV (standard) or stainless steel

DEMISTERS

OPTIMAL RESULTS THANKS TO INERTIAL SEPARATION

Demisters are used in air-conditioning, ventilation and exhaust air systems to reliably separate droplets where required. As each of these applications has its own set of unique requirements, our staff are on hand to provide detailed advice for the design, planning, and implementation of your project.

All of the demisters used by Stemar work according to the principle of inertial separation widely used today. Inertial separation demisters consist of individual long profiles shaped for the relevant application placed next to each other at set distances depending on the application. When air laden with droplets flows through the demister, the drops collect in the demister pad – following the inertia effect – and are discharged through the guide ribs. Demisters vary in size, material and profile placement depending on the application criteria.

STEMAR L-ES DEMISTERS OFFER A WIDE VARIETY OF SIGNIFICANT ADVANTAGES:

• Optimal efficiency for the entire system due to high degree of separation

• Maximum droplet diameter up to 10 micron

• Available as ready-to-install units or as a complete kit including all mounting parts

• Select between either PPTV (standard) or stainless steel

DOWNLOAD THE CORRESPONDING DATA SHEETS TO LEARN MORE ABOUT THE INDIVIDUAL DEMISTER VERSIONS:

T100/T100E

T100_T100E.pdf

T200/T200E

T200_T200E.pdf

T400

T400.pdf

T400-1

T400-1.pdf

T500

T500.pdf

UV DISINFECTION

WATER DISINFECTION WITH POWERFUL UV-C LAMPS

A number of options are available for water disinfection depending on the construction:

Continuous-flow reactors are fitted into tubes and designed to facilitate the required volume flows.

By contrast, immersion lamps require the installation of tanks in the humidifier/scrubber to ensure optimum irradiation of the entire water area.

The Stemar L-ES immersion lamp system features powerful UV-C to effectively kill microorganisms and prevent algae growth. In particular, the disinfection of process and industrial water requires a careful system design. This is why the Stemar L-ES UV-C immersion lamp system was also designed to disinfect cooling towers, fountains, tanks and humidification systems.

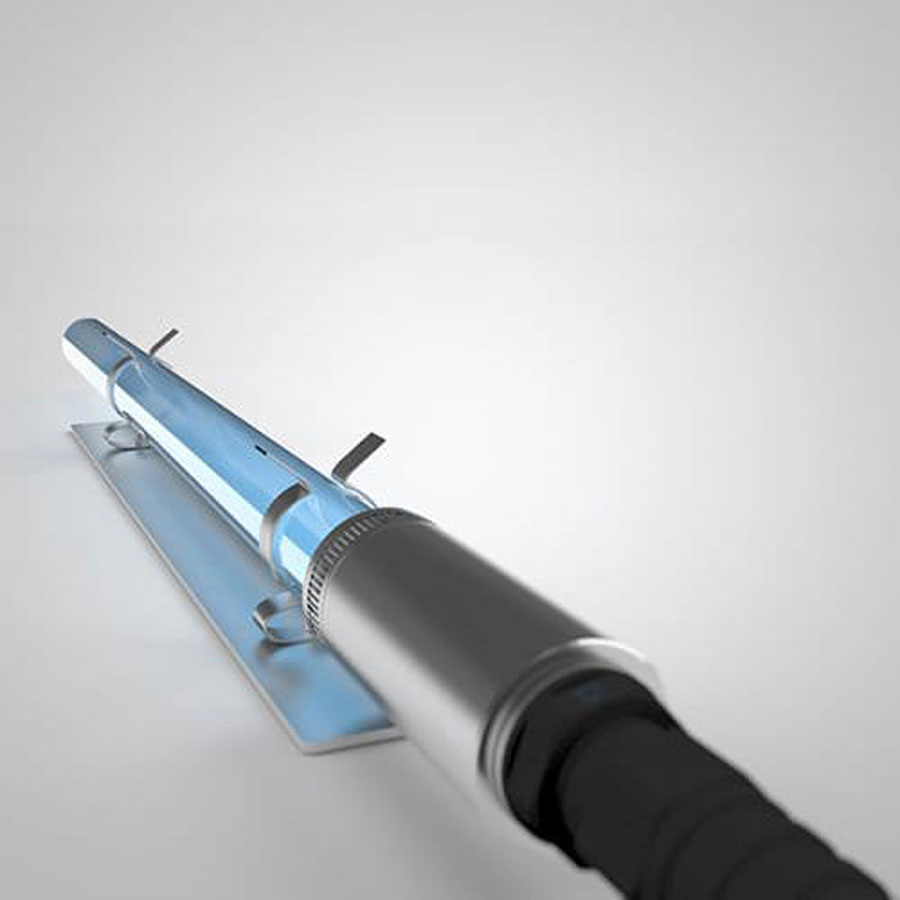

AIR DISINFECTION WITH THE UV-C DUCT MODULE

Air duct hygiene is critical for the volume flow of air intake and circulation systems. UV-C barriers in the air duct help to prevent germs from entering the external air intake and stop microorganisms spreading through the circulation system.

Our air duct modules can be inserted directly into air ducts, facilitating simple use of UV-C technology in air intake and circulation systems. If the ducts are difficult to access, installation can be performed from outside using UV-C flange modules.

Both systems are also suitable for high volume flows and do not generate any additional air resistance. Maximum flexibility is guaranteed by a wide range of tube lengths and types, which allow a perfect fit, even in the case of adverse environmental conditions. The precise calculations for the tube allow optimal project planning, creating the perfect conditions for faultless functioning of your air-conditioning unit.

UV DISINFECTION

WATER DISINFECTION WITH POWERFUL UV-C LAMPS

A number of options are available for water disinfection depending on the construction:

Continuous-flow reactors are fitted into tubes and designed to facilitate the required volume flows.

By contrast, immersion lamps require the installation of tanks in the humidifier/scrubber to ensure optimum irradiation of the entire water area.

The Stemar L-ES immersion lamp system features powerful UV-C to effectively kill microorganisms and prevent algae growth. In particular, the disinfection of process and industrial water requires a careful system design. This is why the Stemar L-ES UV-C immersion lamp system was also designed to disinfect cooling towers, fountains, tanks and humidification systems.

AIR DISINFECTION WITH THE UV-C DUCT MODULE

Air duct hygiene is critical for the volume flow of air intake and circulation systems. UV-C barriers in the air duct help to prevent germs from entering the external air intake and stop microorganisms spreading through the circulation system.

Our air duct modules can be inserted directly into air ducts, facilitating simple use of UV-C technology in air intake and circulation systems. If the ducts are difficult to access, installation can be performed from outside using UV-C flange modules.

Both systems are also suitable for high volume flows and do not generate any additional air resistance. Maximum flexibility is guaranteed by a wide range of tube lengths and types, which allow a perfect fit, even in the case of adverse environmental conditions. The precise calculations for the tube allow optimal project planning, creating the perfect conditions for faultless functioning of your air-conditioning unit.

REFURBISHMENT

OPTIMISATION AND PERFORMANCE ENHANCEMENT

As a manufacturer of air scrubbers and humidifiers, the maintenance and operational safety of existing and production-related units is key. This does not just extend to our own customers or operators.

In order to meet this requirement and ensure costs for upgrading the existing unit remain reasonable, we have developed special retrofitting and refurbishment modules that allow us to bring units, including non-Stemar products, in line with the state-of-the-art at the drop of a hat.

We often also successfully improve humidification performance in the process. The sophisticated module system and our decades of experiences allow us to perform these refurbishments as quickly as possible to limit production interruptions for production equipment. Units are then up-to-date for years. Customers also benefit from easier and therefore more cost-effective maintenance and fulfilment of all applicable hygiene standards.

Needless to say, not every unit is suitable for refurbishment. Depending on the age or condition of the housing, the unit may simply need to be replaced. Benefit from our many years of experience in replacing entire units in no time at all without any structural changes to the building required for installation of the new unit.

Give us a call to receive more information from the STEMAR L-ES team.

REFURBISHMENT

OPTIMISATION AND PERFORMANCE ENHANCEMENT

As a manufacturer of air scrubbers and humidifiers, the maintenance and operational safety of existing and production-related units is key. This does not just extend to our own customers or operators.

In order to meet this requirement and ensure costs for upgrading the existing unit remain reasonable, we have developed special retrofitting and refurbishment modules that allow us to bring units, including non-Stemar products, in line with the state-of-the-art at the drop of a hat.

We often also successfully improve humidification performance in the process. The sophisticated module system and our decades of experiences allow us to perform these refurbishments as quickly as possible to limit production interruptions for production equipment. Units are then up-to-date for years. Customers also benefit from easier and therefore more cost-effective maintenance and fulfilment of all applicable hygiene standards.

Needless to say, not every unit is suitable for refurbishment. Depending on the age or condition of the housing, the unit may simply need to be replaced. Benefit from our many years of experience in replacing entire units in no time at all without any structural changes to the building required for installation of the new unit.

Give us a call to receive more information from the STEMAR L-ES team.

NOZZLES & REPLACEMENT PARTS

STEMAR L-ES HL ATOMISER NOZZLES

Our HL atomiser nozzles are available with a hollow, full cone and are heat-resistant up to 130 degrees, impact-resistant and corrosion-resistant. The nozzles’ large cross sections provide a strong water flow and prevent clogging.

We offer a variety of nozzle ends with outlet holes ranging from 6 to 10 mm for meet our customer’s individual efficiency requirements. Special flat cone inserts are also available for scrubbers with highly-compact dimensions due to their design.

Are quick assembly and disassembly your top priority? If so, try our particularly maintenance-friendly type 1 nozzles with a quick-release clamp for nozzle tubes with a diameter of 40 mm.

AIR SCRUBBER REPLACEMENT PARTS

We keep all replacement parts for humidifiers and scrubbers in stock at all times to ensure they are available for quick delivery. Our replacement parts include:

• Plastic & stainless steel demister profiles

• Plastic & stainless steel rectifier profiles

• Stainless steel float valves

• Stainless steel inspection panels

• UB-C tubes

• Pumps (KSB & Lowara)

• Lamps for humidifiers/scrubbers

• Nozzles

• Solenoid valves

• Shut-off valves

• Level sensors

• Distance bars

• Demister cartridges

• Suction baskets

• Filters

• Nozzle tubes

• Seals

• Heating rods

• Fillings

• Agglomerators

• High pressure replacement parts

• Desalination units

• and much more on request

NOZZLES & REPLACEMENT PARTS

STEMAR L-ES HL ATOMISER NOZZLES

Our HL atomiser nozzles are available with a hollow, full cone and are heat-resistant up to 130 degrees, impact-resistant and corrosion-resistant. The nozzles’ large cross sections provide a strong water flow and prevent clogging.

We offer a variety of nozzle ends with outlet holes ranging from 6 to 10 mm for meet our customer’s individual efficiency requirements. Special flat cone inserts are also available for scrubbers with highly-compact dimensions due to their design.

Are quick assembly and disassembly your top priority? If so, try our particularly maintenance-friendly type 1 nozzles with a quick-release clamp for nozzle tubes with a diameter of 40 mm.

AIR SCRUBBER REPLACEMENT PARTS

We keep all replacement parts for humidifiers and scrubbers in stock at all times to ensure they are available for quick delivery. Our replacement parts include:

• Plastic & stainless steel demister profiles

• Plastic & stainless steel rectifier profiles

• Stainless steel float valves

• Stainless steel inspection panels

• UB-C tubes

• Pumps (KSB & Lowara)

• Lamps for humidifiers/scrubbers

• Nozzles

• Solenoid valves

• Shut-off valves

• Level sensors

• Distance bars

• Demister cartridges

• Suction baskets

• Filters

• Nozzle tubes

• Seals

• Heating rods

• Fillings

• Agglomerators

• High pressure replacement parts

• Desalination units

• and much more on request

SERVICES

UPGRADE YOUR SYSTEMS AND UNITS WITH THE STEMAR L-ES EXPERT TEAM

Whether it’s the refurbishment of old systems, the complete replacement of old units or modifications: Let the Stemar L-ES take care of all aspects for you – from project planning to the design and commissioning.

If your system is outdated, our experienced team will first professionally assess it. We will then provide comprehensive advice on how to update your systems to ensure compliance with VDI 6022.

Do you have a fibreglass unit that functions perfectly except for a leaking tank? We’re happy to help. Stemar L-ES can replace the old tank with a brand-new stainless steel one, putting your unit back into operation in no time at all.

Our team can also install and commission the new unit upon request.

SERVICES

UPGRADE YOUR SYSTEMS AND UNITS WITH THE STEMAR L-ES EXPERT TEAM

Whether it’s the refurbishment of old systems, the complete replacement of old units or modifications: Let the Stemar L-ES take care of all aspects for you – from project planning to the design and commissioning.

If your system is outdated, our experienced team will first professionally assess it. We will then provide comprehensive advice on how to update your systems to ensure compliance with VDI 6022.

Do you have a fibreglass unit that functions perfectly except for a leaking tank? We’re happy to help. Stemar L-ES can replace the old tank with a brand-new stainless steel one, putting your unit back into operation in no time at all.

Our team can also install and commission the new unit upon request.

CHRISTIAN MARTIN

technology & sales · Managing Director

phone +49 7774 / 92 01 43

fax +49 7774 / 92 01 45

KARL MAIER

technology & sales

phone +49 7774 / 92 01 44

fax +49 7774 / 92 01 45

INGE SCHMITZ

orders & shipping

phone +49 7732 / 95 95 61

fax +49 7732 / 95 95 71

JÜRGEN SCHMITZ

technology & sales

phone +49 7732 / 95 95 61

fax +49 7732 / 95 95 71